Price list 2021 (1st half)

| № | Type of equipment | Specifications | Appearance |

| Centrifuges, basic models | |||

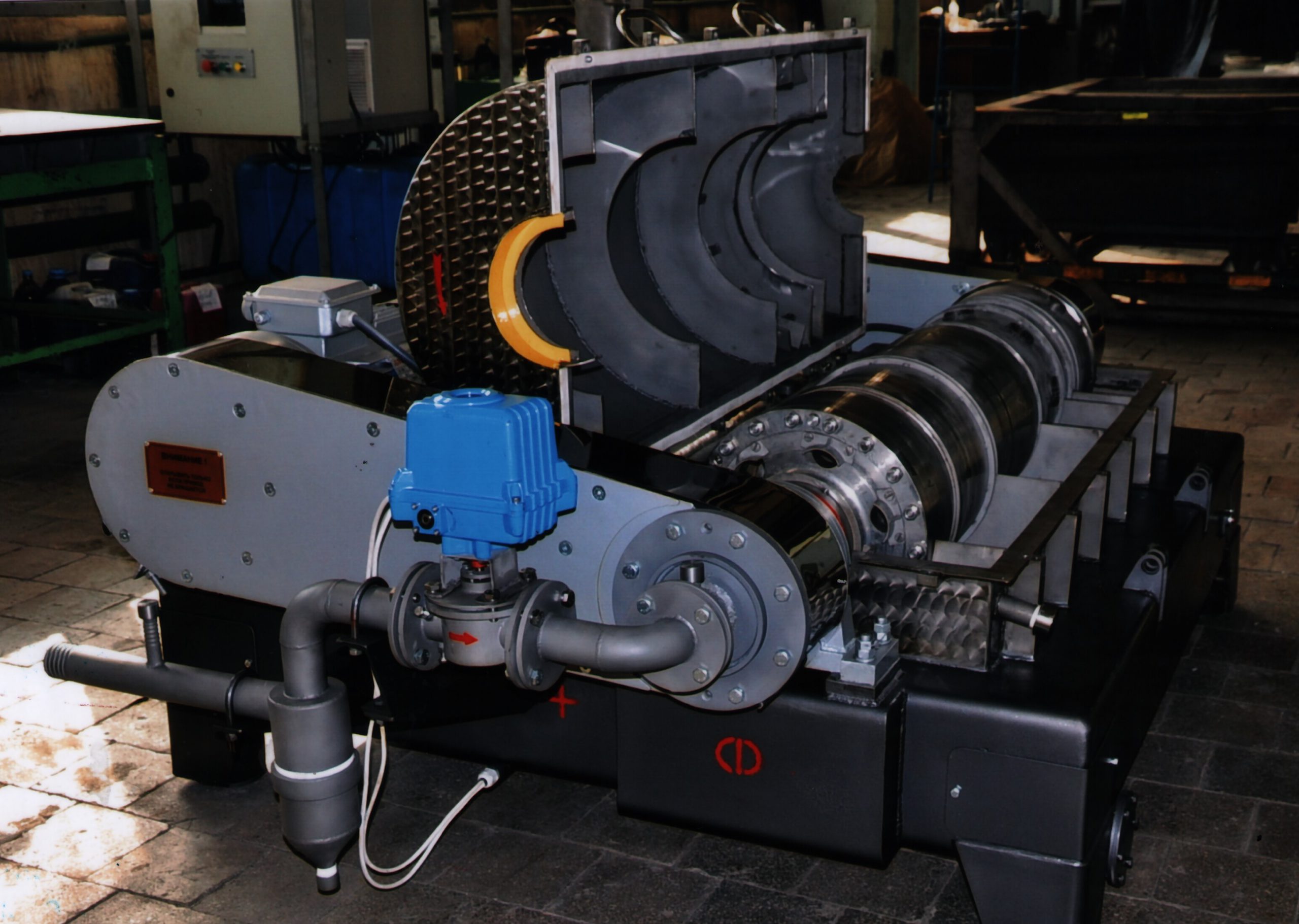

| 1 | Ecomash SHS 311 А | Maximum volumetric capacity (at Fr=1000) – 20 m3/h

Mass productivity (at a solid density in the pulp of 2.5 g/cm3) – 1 t/h Maximum rotor speed – 4000 r/m Demand of the electric motor for the rotor drive – 18.5 kW |

Centrifuge Ecomash SHS 312 S-222 Weight – 1750 kg

Centrifuge Ecomash SHS 311 S-113 Weight – 1950 kg |

| 2 | Ecomash SHS 461 А | Maximum volumetric capacity (at Fr=1000) – 36 m3/h

Mass productivity (at a solid density in the pulp of 2.5 g/cm3) – 5 t/h Maximum rotor speed – 2500 r/m Demand of the electric motor for the rotor drive – 30 kW |

Centrifuge Ecomash SHS 461 A-113 Weight – 3100 kg |

| 3 | Ecomash SHS 511 А | Maximum volumetric capacity (at Fr=1000) – 40 m3/h

Mass productivity (at a solid density in the pulp of 2.5 g/cm3) – 5 t/h Maximum rotor speed – 2500 r/m Demand of the electric motor for the rotor drive – 37 kW |

Centrifuge Ecomash SHS 511 A-113 Weight – 3180 kg |

| 4 | Ecomash SHS 521 А | Maximum volumetric capacity (at Fr=1000) – 50 m3/h

Mass productivity (at a solid density in the pulp of 2.5 g/cm3) – 5 t/h Maximum rotor speed – 2600 r/m Demand of the electric motor for the rotor drive – 55 kW |

Centrifuge Ecomash SHS 521 S-113 Weight – 3900 kg |

| 5 | Ecomash SHS 751 А | Maximum volumetric capacity (at Fr=1000) – 100 m3/h

Mass productivity (at a solid density in the pulp of 2.5 g/cm3) – 20 t/h Maximum rotor speed – 1700 r/m Demand of the electric motor for the rotor drive – 132 kW |

Centrifuge Ecomash SHS 751 A-113 Weight – 10500 kg |

| Drum sieve | |||

| 1 | Drum sieve Ecomash 1308 АS | Water throughput not less that 100 m3/h |  |

| 2 | Drum sieve Ecomash 1310 АS | Water throughput not less that 200 m3/h | |

| Semi-submersible disc pumps | |||

| 1 | Semi-submersible disc pumps | Volumetric water capacity – 10…100 m3/h

Maximum water pressure at the pump outlet – 1,2 bar |

|

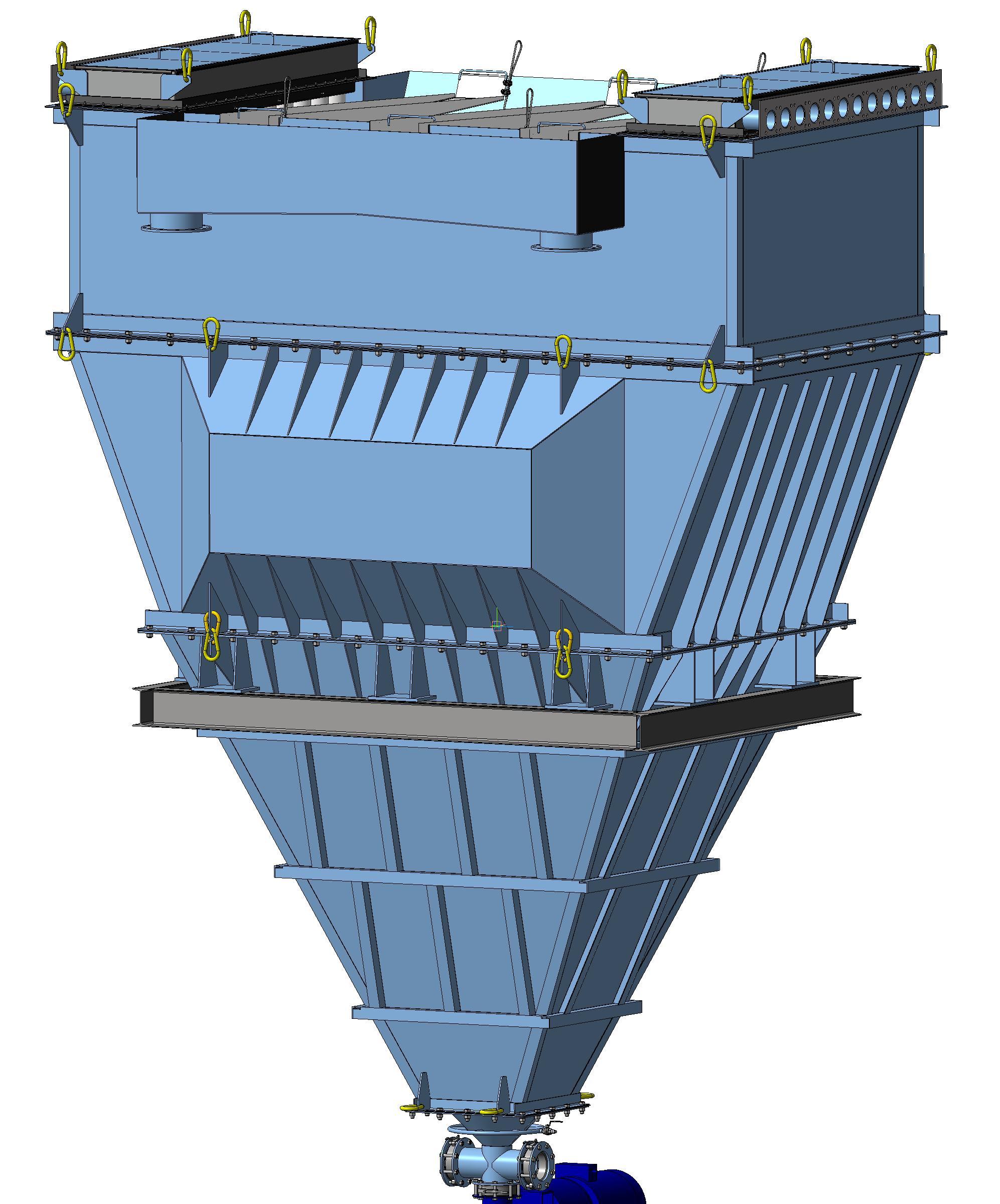

| Thin-layer thickening tanks | |||

| 1 | Thin-layer thickening tanks | Volumetric water capacity – 60…400 m3/h |  |

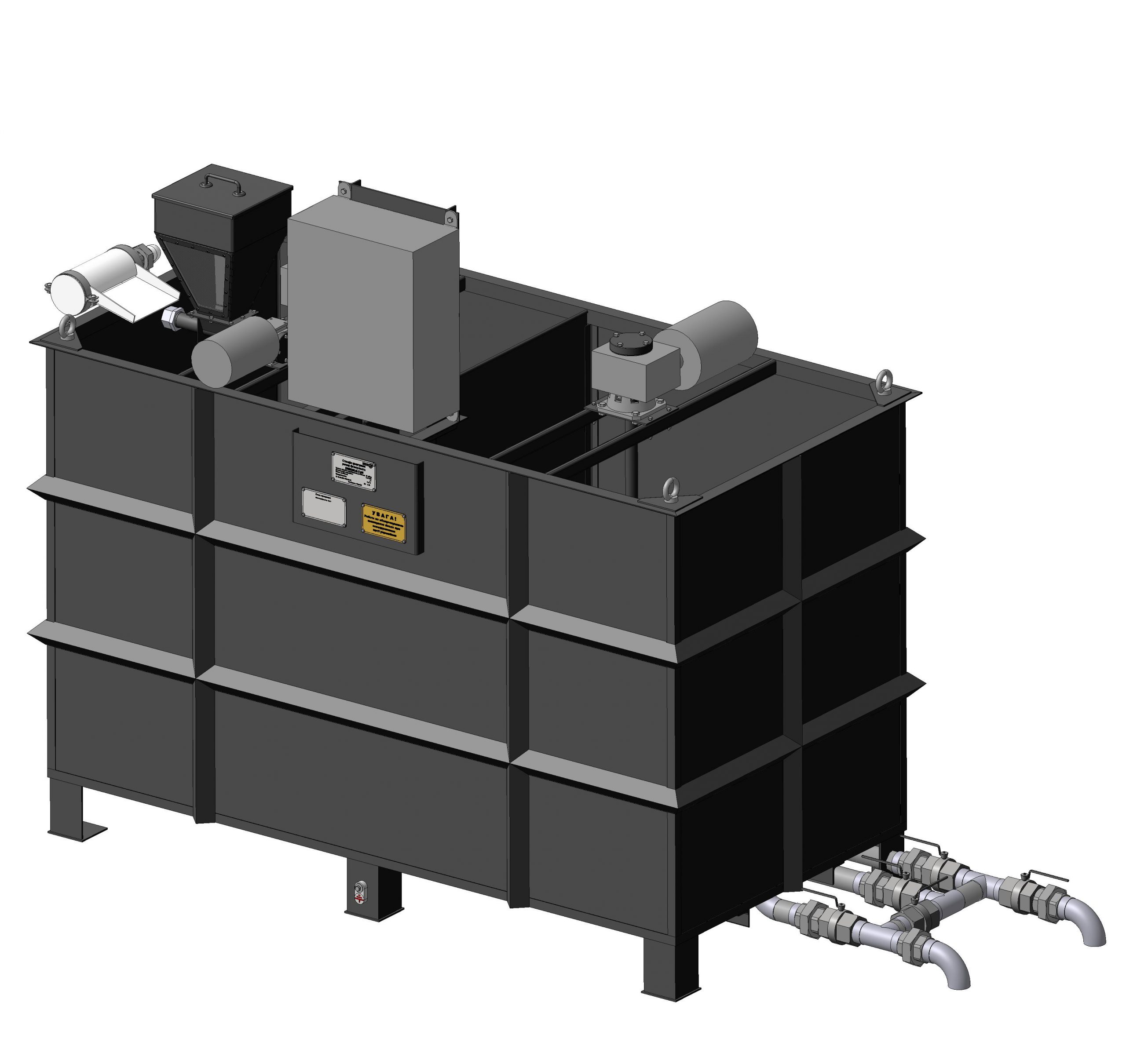

| Flocculant preparation and dosing station | |||

| 1 | Flocculant preparation and dosing stations | Flocculant preparation and dosing stations 1…10 kg/h |  |

Material designations used:

S – stainless steel;

A – structural alloy steel;

С – carbon steel.